Home / Flow Testing Machine

Flow Testing Machine

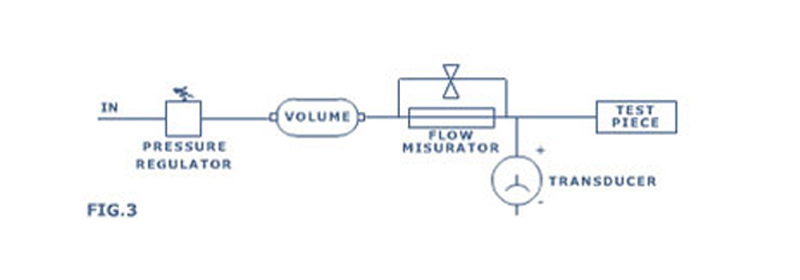

This system allows to measure in a direct way the flow rate or airflow generated by the leak. At the end of the filling and settlement phases the test time is the only factor which is necessary in order to obtain a stable measure about this flow: this time is generally very short (ex.: 0,1 Sec.).

Endurance Testing Machine

These machine are used to cheak fatigue is the weakening of a material caused loads. It is the progressive and localised structural damage that occurs when a material is subjected to cyclic loading.

This system is essentially made up of a flow sensor, a pressure sensor and a constant pressure generator in the range of the measurement flow. The pneumatic complexity of the system is in the possibility to give a constant pressure flux but without any bobbing and noises because, unlike Δ, p systems, the measure is in open pressure force.

The flow measure can be done using volumetric temperature-compensated systems or actually, through massive meters.

The practical application of these instruments for the leaks measure takes place in four cases:

when the volume of the detail is not known and variable: for example very flexible packs or bottles;

when the test times must be reduced at most;

when it is necessary a continuous measurement of the leak in order to execute analysis and repairs;

When the leakages which must be measured are so elevated that a Δp system cannot maintain a constant test pressure distorting the leakage calculation of the same: cartridge valves or oil distributors, drawings in general.